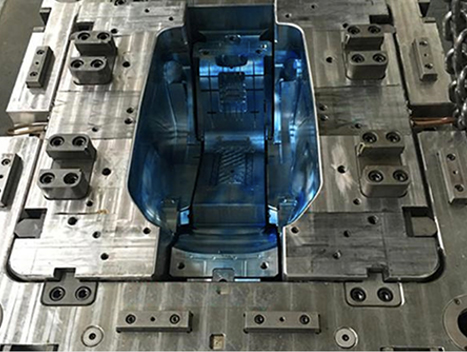

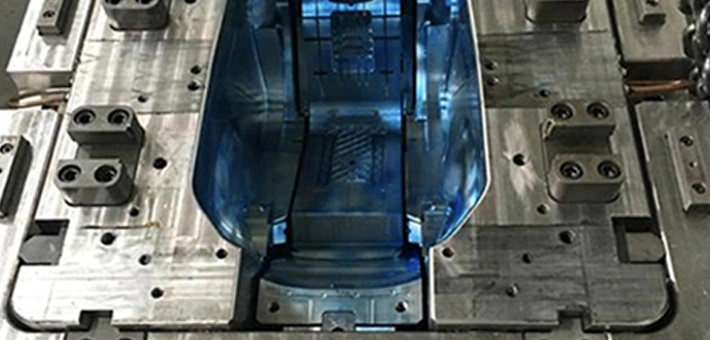

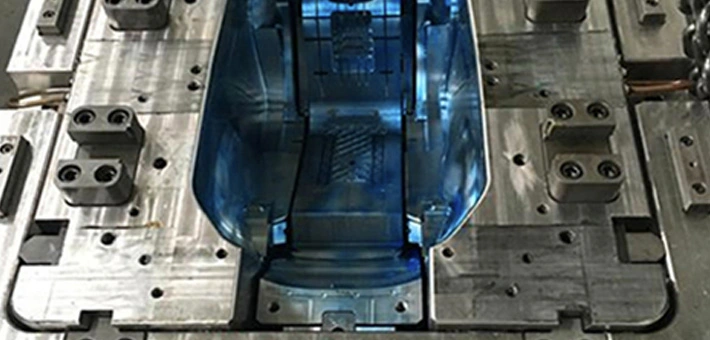

Home appliance moulds play a crucial role in the injection molding industry. Their processing and customization is a complex and precise craft process. The following will provide a detailed introducti...

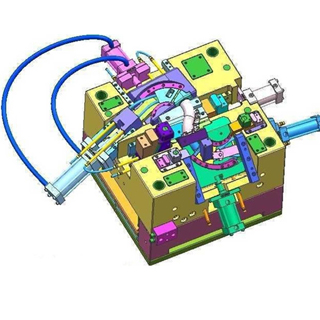

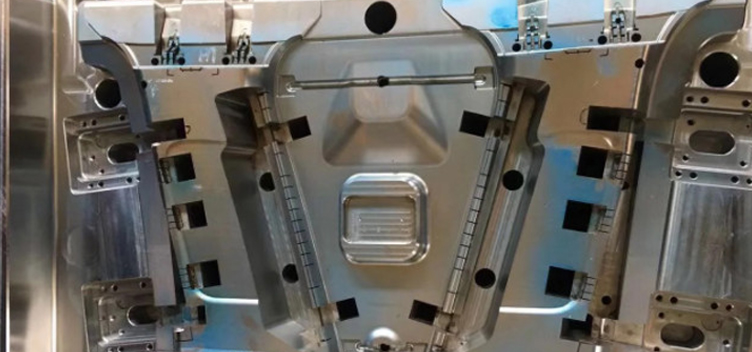

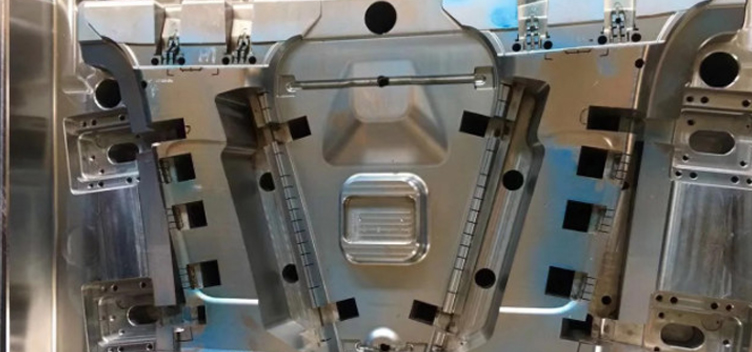

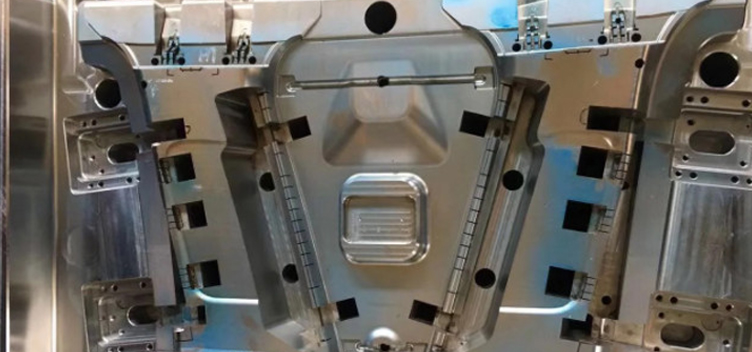

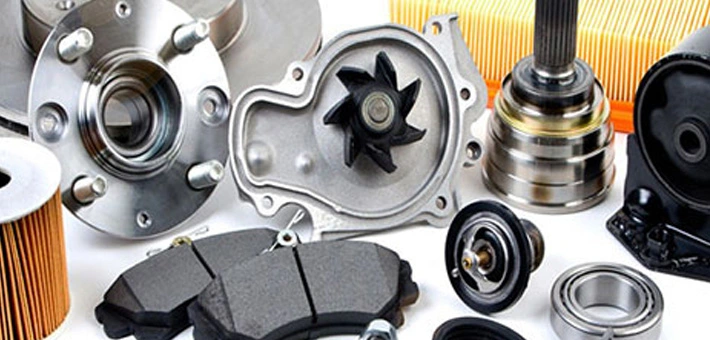

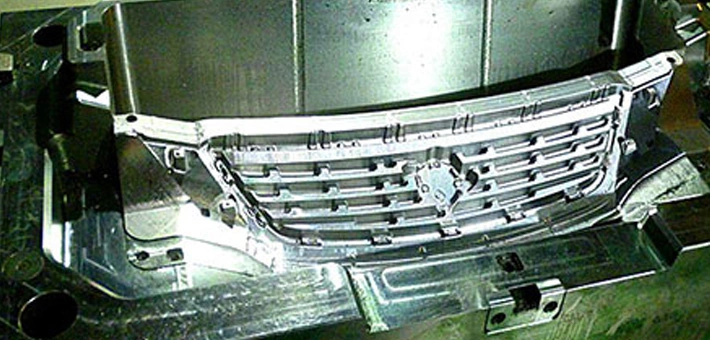

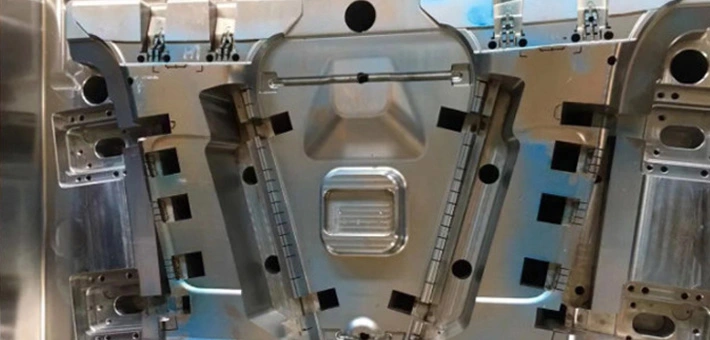

Auto part mould is a complex and sophisticated system designed to meet the demands of high precision, high quality, and complex shapes in auto part production. Here is a detailed analysis of the struc...

The choice of material of auto part mould is crucial for the performance, durability, and final product quality and cost of the mould. Different materials have their unique characteristics and applica...

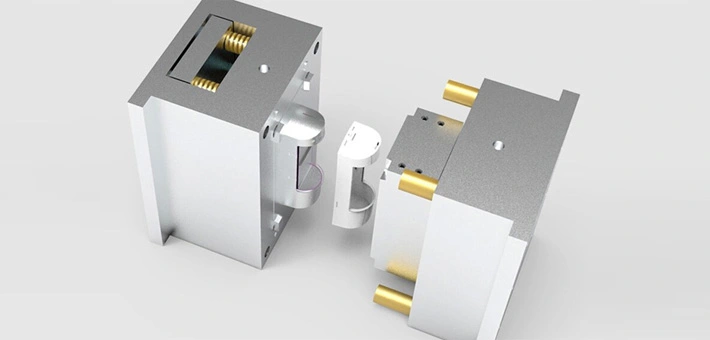

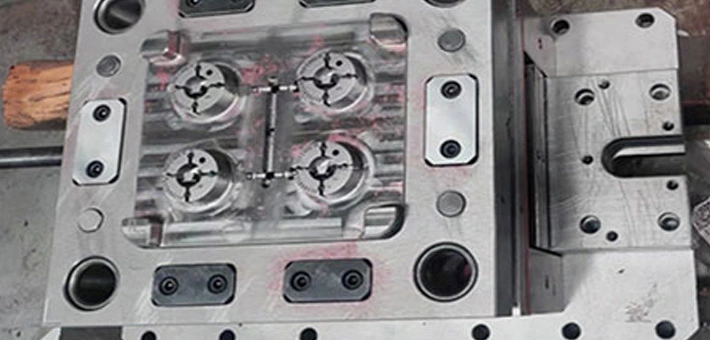

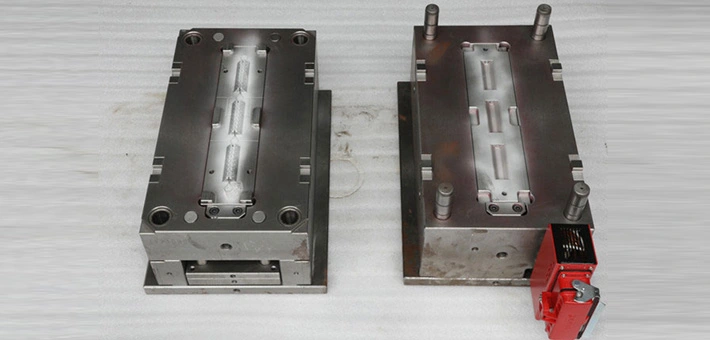

As the primary input device for computers, the quality and design of computer keyboard keys directly affect the user experience. In the manufacturing process of keyboards, the design of keyboard mould...

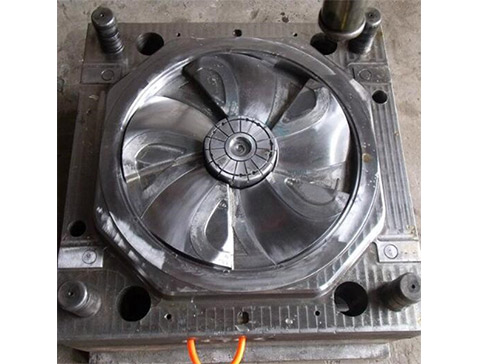

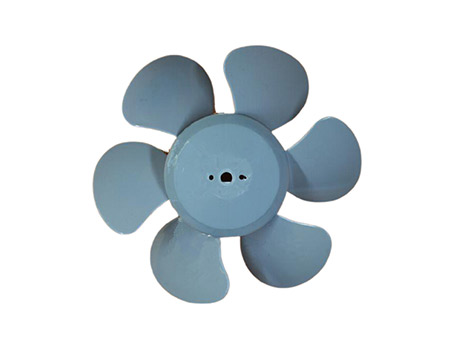

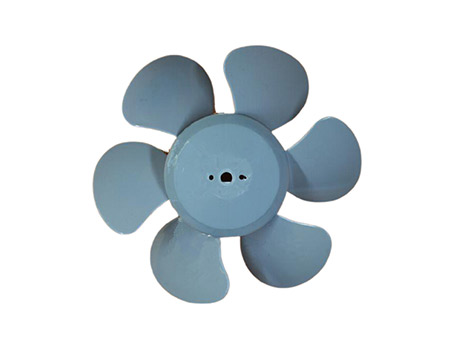

In the manufacturing industry,fan blade mould is key tool for fan production. Their quality and performance have a crucial impact on the overall quality of the fan. Therefore, mastering the maintenanc...

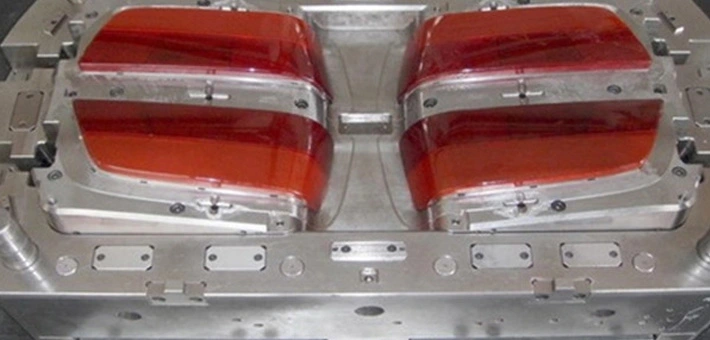

When it comes to manufacturing car parts, precision and attention to detail are essential. This is especially true when it comes to designing headlights and taillights, as these components not only pl...

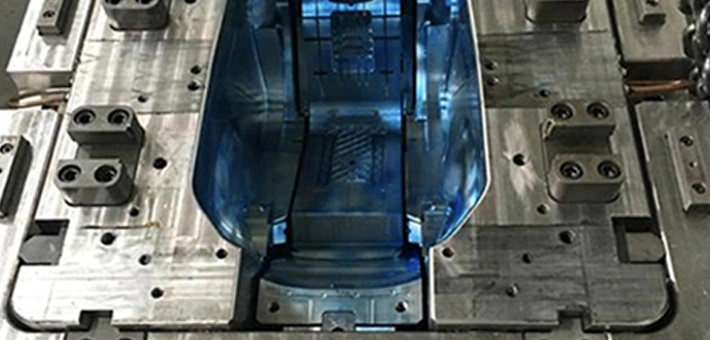

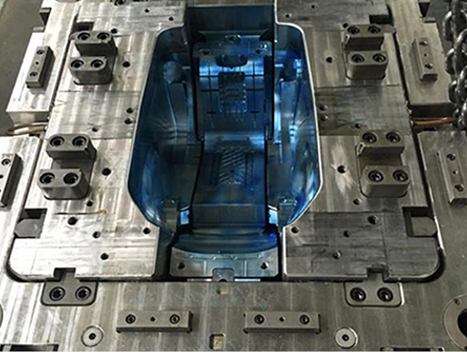

As we go about our daily lives, we often take for granted the convenience and efficiency of our home appliances. From refrigerators to washing machines to microwaves, these essential gadgets make our ...

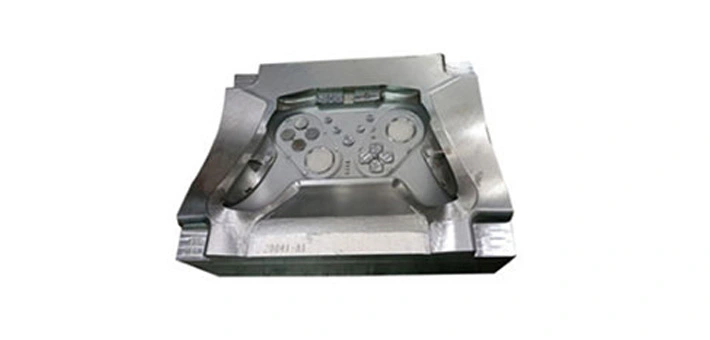

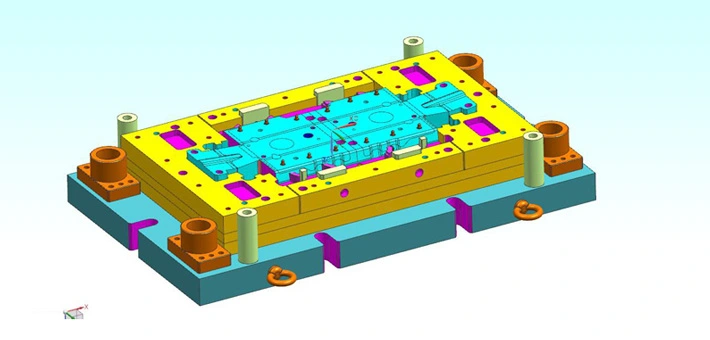

As a brand that specializes in manufacturing injection molds, we understand the crucial role that injection mold designers play in our industry. From concept to final production, injection mold design...

The Foundations of Automotive PrecisionIn the intricate world of automotive manufacturing, precision is not just a requirement; it's a fundamental necessity. At the heart of this precision lies th...

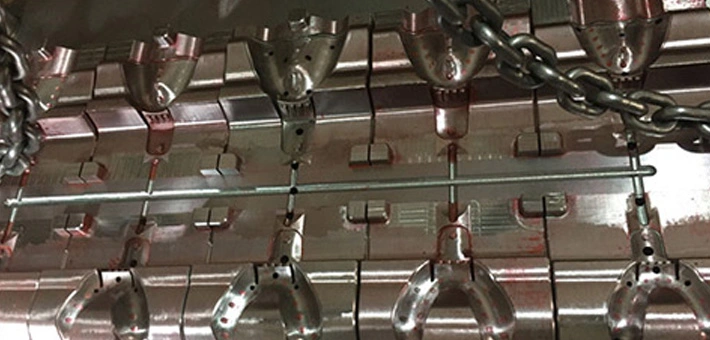

Industrial moulds play a crucial role in the metal casting processes of various industries. From automotive to aerospace, these moulds are essential in creating precise and complex metal components. I...

In the world of electronics manufacturing, the use of molds plays a crucial role in the production of various components. One area where molds are particularly important is in the manufacturing of bat...

When it comes to producing electronic devices, one crucial step in the manufacturing process is electronics mold. This process involves creating a mold that will be used to form the outer casing of th...

In the constantly evolving world of electronics manufacturing, the ability to produce high-quality and sustainable products is more crucial than ever. One key component of this process is the use of e...

In the intricate dance of automotive engineering, the role of plastic auto parts moulds is a silent yet influential partner in shaping the performance and efficiency of vehicles. From intricate car pa...

The production of high-quality plastic auto parts hinges on the precision and reliability of the mould used in the manufacturing process. Selecting the right plastic auto parts mould manufacturer is a...

Green Vitality Industry: Revolutionizing Home Appliance Mould ManufacturingIn today's fast-paced world, efficiency and convenience are the keywords to success. And no other industry exemplifies th...

Home is where we find solace and comfort, and with the advancements in technology, our homes have become more than just a shelter. The introduction of home appliances has revolutionized the way we liv...

In the rapidly evolving world of technology, electronics play a vital role in our everyday lives. From smartphones to smart appliances, electronic devices connect us to the digital world and simplify ...

The world we live in today is heavily reliant on electronic gadgets. From smartphones and laptops to smart TVs and wearable devices, these innovations have become an integral part of our daily lives. ...

In today's fast-paced world, maintaining a vehicle's performance and reliability is crucial. One critical aspect of vehicle maintenance is the replacement of faulty or worn-out car parts. Prev...

In the world of automotive manufacturing, car parts moulding plays a crucial role. It ensures that the various components of a vehicle are produced accurately and efficiently. However, the success of ...

When we drive a car, we rarely stop to think about the intricate process that goes into designing the various parts that make up our vehicles. One crucial aspect of this process is the creation of car...

In the dynamic landscape of automotive manufacturing, the efficiency of plastic auto parts moulding plays a pivotal role in shaping the success and competitiveness of manufacturers. This passage explo...

The world of car parts moulding is undergoing dynamic changes as manufacturers seek to adapt to evolving technological landscapes and meet the demands of a rapidly changing automotive industry. From a...

In an era where environmental consciousness is paramount, the automotive industry is undergoing a paradigm shift toward more sustainable practices. Car parts moulding, a fundamental aspect of automoti...

Car parts moulding is a cornerstone in the automotive manufacturing process, where precision and durability are paramount. The materials and techniques employed in the creation of car parts moulds sig...

In the competitive landscape of appliance manufacturing, cost management and quality assurance in appliance moulds are integral components of achieving economic success. This passage delves into the s...

In the ever-evolving landscape of appliance manufacturing, design innovations in moulding processes play a pivotal role in shaping the form, function, and appeal of modern appliances. This passage exp...

In the realm of appliance manufacturing, a paradigm shift is occurring as the industry places an increasing emphasis on sustainability. This passage delves into the innovative and eco-conscious practi...

In an era marked by growing environmental awareness, the automotive industry is undergoing a transformative shift towards eco-friendly practices, and plastic auto parts moulding is no exception. This ...

In the world of automotive design and manufacturing, precision is the name of the game. Every detail matters, especially when it comes to critical components like auto lamp moulds. These precision-eng...

Injection molding is a highly versatile and widely used manufacturing process that has revolutionized the production of various components and products across industries. In this essay, we will explor...

When we think of automotive lighting, we often focus on the brilliance of the bulbs and the sleekness of the design. However, behind the scenes, there's an unsung hero that plays a pivotal role in...

The automotive industry has always been at the forefront of technological advancements, and this extends to the manufacturing of car parts. Key to this innovation is the continuous development of car ...

Typing has become an integral part of our daily lives, whether we're working on a computer, sending emails, or even texting on our smartphones. The comfort and efficiency of our typing experience ...

When it comes to household appliances, there's no denying that aesthetic appeal and functionality go hand in hand. One crucial element that plays a pivotal role in shaping these appliances is the ...

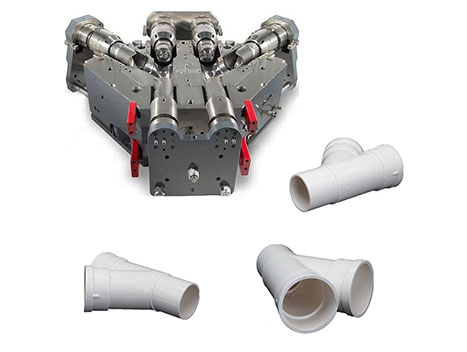

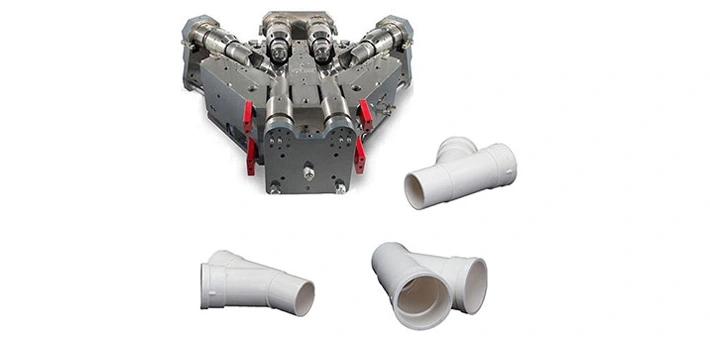

With the development of the plastics industry, the application scope of plastic products is constantly expanding. Industrial plastics are also constantly improving in terms of strength. The amount of ...

The mold for plastic is the tool for giving plastic products complete structure and size in the plastic processing industry. Due to the various types of plastics and processing methods, as well as the...

We encounter various plastic products and accessories in our production and life, most of which are manufactured through injection molding molds. The advantage of using injection molding molds is that...

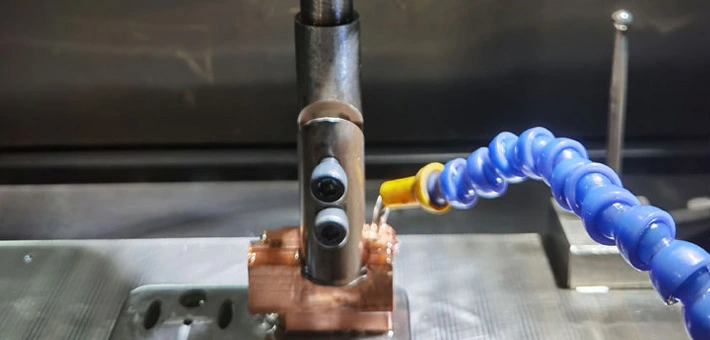

What are the effects of temperature on injection molding prototyping molds, why does temperature affect the molding of injection molds, and how to properly select the temperature during mold forming? ...

When it comes to the development of injection molds, it is not an easy task. Not only does the development of injection molds require a lot of production costs, but it also requires communication and ...

Preparation before injection mold design(1) Design task book;(2) Familiarize with the plastic, including its geometry, the requirements for use of the plastic, and the raw material of the plastic;(3) ...

Injection mold hot runner and cold runnerCold runner: refers to the part between the mold gate and the product gate. The plastic stays in the runner by injection pressure and its own heat. The runner ...

What is injection molds? Can it help my enterprise? Many people may not understand what injection molds are when they first hear this name. This article hopes to help you better understand injection m...

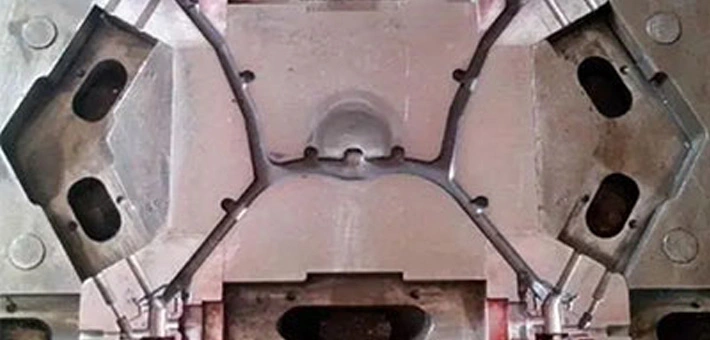

In recent years, the rapid development of the automotive industry has greatly driven the development of the automotive mold industry. Since automotive parts molds are technical products and typical cu...

Common problems with die casting moldsDie casting molds are a method of casting liquid metal using a specialized die casting machine. The basic process involves low or high-speed casting of the metal ...

Factors to consider for injection molds, different customers have different answersWhen choosing molds, many customers are highly price sensitive and even use price as the only criterion for mold sele...

Reasons for injection mold trialDuring the production of injection molds, there may be failures in the injection parts, which are mostly caused by the injection and molding stages of the injection mol...

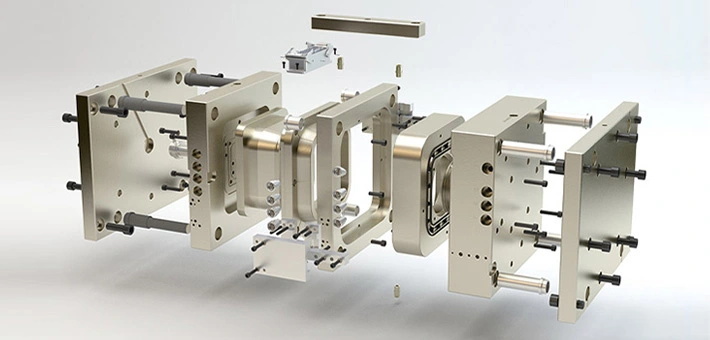

Injection molds are composed of many steel plates and various parts, generally including molding devices, positioning devices, cooling systems, constant temperature systems, runner systems, etc. Accor...

The application of injection molds in our daily life is very extensive. Injection molding, also known as injection molding, is a molding method that combines injection and molding. The advantages of i...

We often fail in mold processing due to various factors, such as shrinkage and depression in the products during injection molding. Don't worry, it is generally caused by the following four points...

Injection molds often need to pay attention to material selection. Using different materials for mold making can have different effects. Choosing good materials is important as it can increase the ser...

As we all know, plastic moulds have many requirements for materials, especially for some large mould processing factories, the requirements for materials are even more stringent. So what are the gener...

Injection mold quality is mainly determined by the material selection of the injection mold. The quality of the mold directly depends on the material selection, so what are the basic requirements for ...

Sometimes we find that the reason for the poor quality of injection mould design and processing is not necessarily due to the quality of the mould, but rather due to improper installation and adjustme...

Currently, aluminum die casting molds are widely used in the mold industry due to their long production cycle, high investment and high precision, resulting in relatively high manufacturing costs. How...

The quality and productivity of die casting parts largely depend on whether the thermal balance control of die casting molds is correct. Effective control and regulation of the thermal balance of the ...

Thermoset plastic molding processing began in the early 1960s, and its products have been developed rapidly and widely used due to their high heat resistance, deformation resistance and good electrica...

Thermosetting plastic injection molding uses a screw or a plunger to pass the polymer through a heated barrel to reduce the viscosity, and then injects it into a heated mold. Once the material fills t...

Molds are process equipment for the production of industrial products, mainly used in manufacturing. It is matched with stamping, forging, casting and forming machinery, and forming machinery for form...

Injection molds are important process equipment for the production of various industrial products. With the rapid development of the plastics industry and the popularization and application of plastic...

Injection moulding die is a tool for producing plastic products; it is also a tool for giving plastic products complete structure and precise dimensions. injection moulding dieing is a processing meth...

Conventional overall quenching has been difficult to meet the high surface wear resistance and toughness requirements of the die-casting mold. Surface strengthening treatment can not only improve the ...

Precision injection parts are produced through injection mold processing, and the quality of mold in injection moldings will directly affect the time cost of injection molding, the quality of injectio...

In the injection molding of plastic parts, there are many factors that affect the quality of injection molding plastic parts, but after the plastic raw materials, injection molding machine and mold st...

Precision injection molding molds are different from ordinary injection molding processes in the word "precision", that is, higher requirements, smaller tolerances, and more beautiful appear...

As plasticization has become a major development trend in today's international automobile manufacturing industry, most of the interior and exterior of automobiles are made of injection molded par...

1. Inspection of injection mold drawingsThe injection mold debugging must be prepared according to the mold debugging notice issued by the external cooperation department or the production department....

The control of the surface temperature of the die-casting mold is very important for the production of high-quality die-casting parts. Uneven or inappropriate die-casting mold temperature will also le...

The heat treatment process is widely used in the manufacture of die-casting molds , which can improve the performance of mold parts and prolong the service life of the mold. In addition, heat treatmen...

In the automotive sector, injection molding is one of the main methods manufacturers use to form plastic parts. However, it's difficult to list the plastic parts in a car produced using injection ...

Injection molding is one of the most commonly used production processes for plastics. Because it provides a viable solution for mass production of high-quality injection-molded automotive parts from a...

In mold design, car molds have always been the molds that everyone thinks are difficult. Sometimes it is difficult to get a product. Today, I will share with you a set of classic car lamp mold structu...

Soapboxes are so common in our life that almost every family uses them. There are also a variety of soapboxes in the market with different shapes.

Medical plastic injection is a method used to manufacture plastic or silicone components for medical purposes. Plastic or silicone components are likely to contain devices for surgical treatment or components to be placed inside the body.

The Thermoset injection molding process is the process of thermoset injection molding using a screw or a plunger to put the polymer into a heated barrel to reduce viscosity and then into a heated mold.

The car seat mainly consists of two parts which are the seat fabric and the seat frame, so the car seat mould should also pay attention to these points.

An injection moulding dies used in affordable injection molding is usually made of steel or aluminum, as a custom tool.