One computer mouse usually includes these plastic parts: a bottom shell, an upper cover, a middle cover, a wheel, a base of wheel, a frame which connects with electronic elements etc. These plastic parts are required not only to be textured well, but also to be wear-resistant. In addition, because it is an electronic housing, it needs to be assembled with electronic components, so the precision requirements for plastic products are relatively high. Green Vitality provide high quality mouse molds within a very short time. Our customers are satisfied with our professionalism and service in the area of mouse molding.

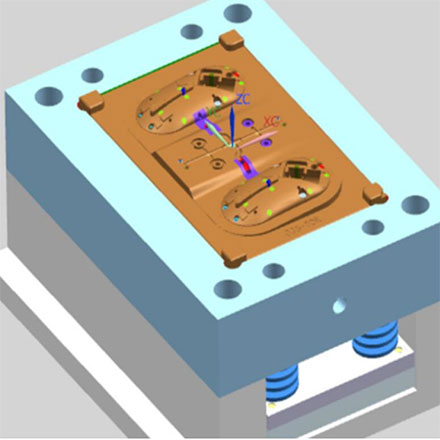

| Description | Computer Mouse Plastic Injection Mold |

| Plastic material | ABS |

| Part dimension(mm) | 110*60*30mm |

| Mould dimension(mm) | 280*380*250 |

| Mould weight (KG) | 200KG |

| Mould cavity&core steel | 718 |

| Nos of Cavity | 4 |

| Manufacture time (day) | 35days |

| Mould life | ≥500000 |

| Molding cycle (S) | The 30s |

| Mold Package | Vacuum packing |

| Pre-wood case |

Green Vitality Industry is a professional plastic mold and molding manufacturer which has 25years of experience in the plastic mold industry. We have below advantages in the computer mouse mold area which our customers benefit from us and we grow up as well thanks to our customers' trust and support.

Electronic Injection Molding Experts

Flexible OEM service is available, Steady Engineering team provides advice and solution to part moldability and error prevention for the overall project purpose.

Commitment to Quality

We believe in and practice the "Quality is of Prime Importance" philosophy. Well-versed manufacturing team to manage the mold machining and injection processing. QA department performs strong quality assurance in order that all products and services meet or exceed the expecting needs.

Competitive Price

With diversity in equipment capabilities and in-depth knowledge about industrial injection mold, Green Vitality is able to offer competitive prices for mice moulds and services reasonably.

In-time Delivery

The professional team creates and executes the most efficient schedule for the respective project task, and helps arrange delivery at the economical possible cost.

As a computer mouse mold manufacturer, our dedication to precision and innovation sets us apart. We specialize in OEM services, crafting custom computer mouse mould production. Our state-of-the-art facilities are equipped with cutting-edge technology to ensure the highest quality mice moulds. We understand the importance of ergonomic designs and functionality in today's competitive market. Our team of skilled engineers and designers collaborates closely with clients to bring their vision to life. We take pride in our ability to create molds that produce mice with flawless form and function. Trust us to be your partner in shaping the future of computer mice.

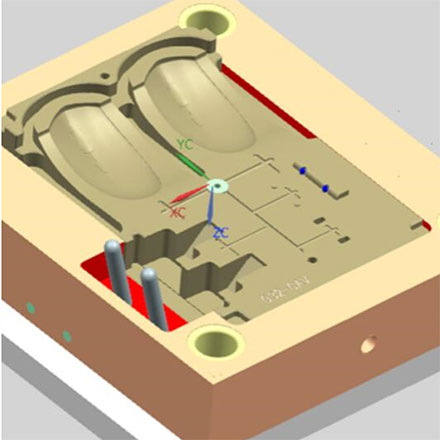

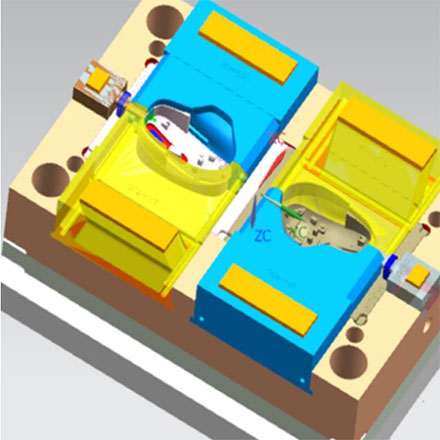

To produce a high qualifed computer mouse mold, we need to work hard on mold design and analyze injection, ejection and cooling system, so that the gamepad is without flash, sinkmark, deformation and easy demoulding. These are very important factors when making gamepad mold and injection the parts. Our aim is once the injection parameter is setted by our customers, the mass production will be continuously good and no need to repair the mice moulds.

Before making a production mold, we usually verify the plastic product & mold in the following steps. In this way, we can speed up product development, effectively control mouse mould costs, reduce mouse mould repair costs in the manufacturing stage, and fully verify product performance as much as possible to save time and cost.

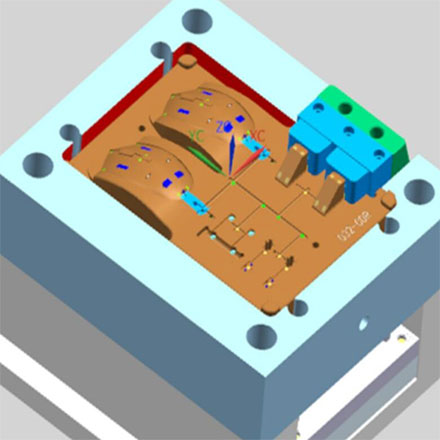

The prototype part is not only visible, but also can be assembled, it can intuitively reflect whether the structure of mice mold is reasonable or not, and the difficulty of installation. It is convenient to detect and solve problems in the early stage. Usually made by rapid prototyping parts, CNC processed rapid prototypes, and 3D printing within 1 week.

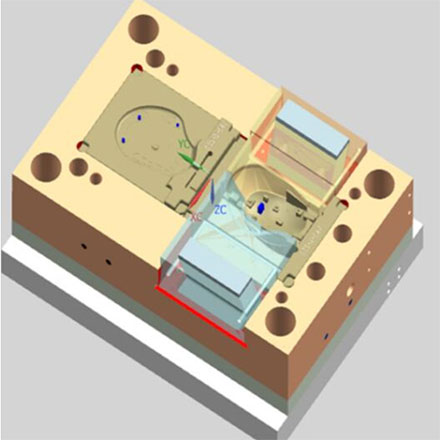

After the prototype parts verification, we will improve the problems found, and then carry out a small batch assembly test. In addition, in order to carry out more sufficient verification and avoid the risk of mouse mold scrap, usually at this stage, we will first develop a lower cost soft mold to verify the mold structure and mold mouse feasibility, and the material and structure of the parts are the same to mass-produced parts. Soft molds can typically produce no more than 10,000 shots.

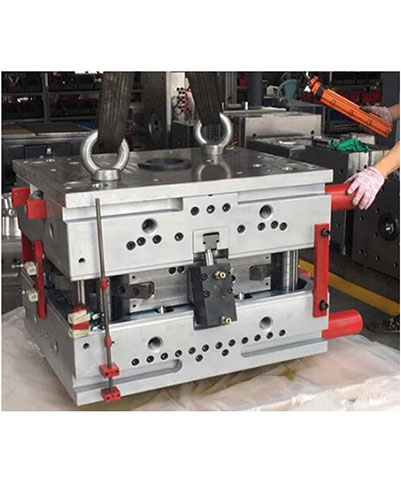

After the parts have been fully verified and approved, the official steel computer mouse mold is developed. The official steel mice moulds can produce 200000, 500000, or 1000000 parts according to different steel materials used, and select the appropriate steel material according to the planned output.