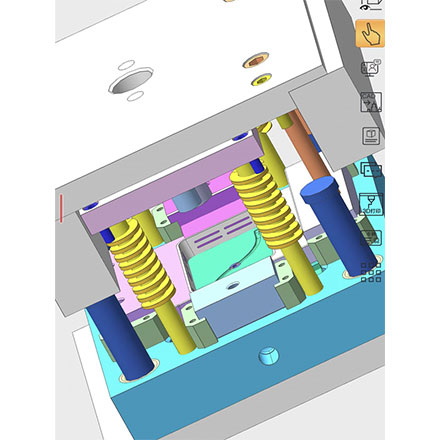

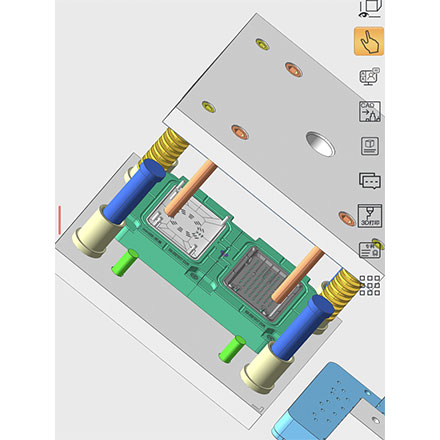

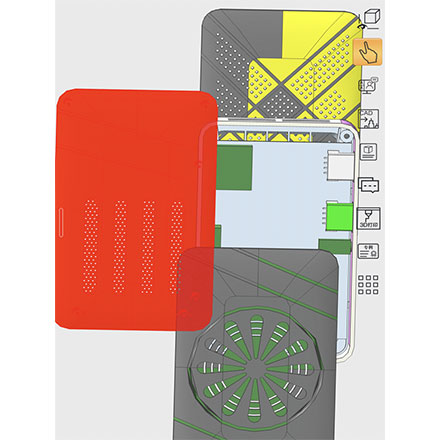

Our molds take into account the properties of this material, so the mold usually be designed as 1+1 or 2 cavities based on the quantity requirements. Also we will use subgate to meet the performance requirements of the product and the mold. In addition, the product of this set top box has a lot of small heat dissipation holes. so we should pay more attention to the mold design. As there are too many holes. If the design is not good, the product may be flash or short shot, so we designed it with multiple points of gates to meet product requirements.

The shell of the set-top box is generally divided into an upper cover and a lower shell. During the processing of the set-top box shell mold, improper design of the runner can easily cause the product to be formed with low precision and low quality and even cause the product to be directly scrapped, which seriously affects the processing efficiency and quality of the mold.

And the high-cost input is not conducive to the improvement of enterprise benefits. In addition, most of these kinds of plastic mold products have polishing requirements, some are made into black transparent shells. Green Vitality Industry generally use S136 for mold steel to ensure the life of the mold. Due to the function of the product, we usually need to use fire-resistant plastic materials to ensure the safe use of the product.

| Description | Set-Top Box Plastic Injection Mold |

| Plastic material | ABS |

| Mould dimension(mm) | 350*550*360 |

| Mould weight (kg) | 510kg |

| Mould cavity&core steel | S136 |

| Nos of Cavity | 1+1 |

| Manufacture time (day) | 30 days |

| Mould life | ≥300 000 |

| Molding cycle (S) | 45s |

| Mold Characteristics | Get the perfect part for production after the first trial |

| Short cycle time |

ISO9001:2015 certified factory with competitive price & own Export License;

Professional engineer and QC Team, over 75% with more than 10 years of experience in the plastic injection mold industry.

Perfect service, 7x24 hours stand by;

Faster Delivery Time, Mold 3~6 weeks, Mass production 7~10 days;

One-stop service provider from the initial product design and development to the entire stage of mold making and product production and delivery.

Most of the set-top box molds we made are mainly left in our factory to make products for our customers.

During the continuous working process, the molds are likely to cause problems such as wear of parts, deterioration of lubricants, water leakage, and crushing of plastic materials. Therefore, it is necessary to maintain the mold.

Regular dusting (appearance, PL surface, cavity, core, etc.)

Re-add lubricant regularly (ejection mechanism, slider, etc.)

Regular replacement of wear parts (tie rods, bolts, etc.)