Step 01. Mold Flow & Mold Design: The first stage of mold development is mold flow & mold design stage. By analyzing the mold flow analysis data, we eliminate the potential problems in the product production phase in advance.

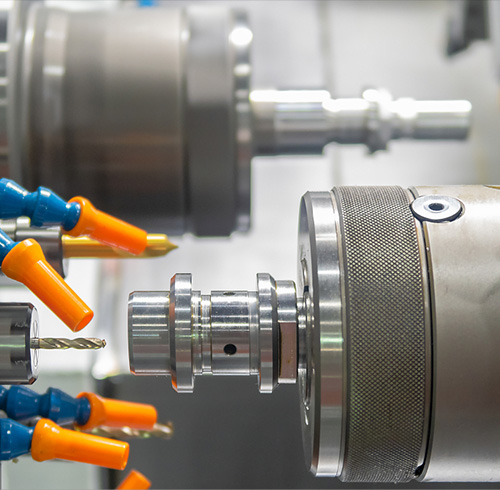

Step 02. CAM Tooling: Once the analysis step is completed, the data created using the CAM program is input into the numerical control machine (NC, CNC, Milling, etc.) and then machining begins.

Step 03. Manufacture & Tool Trial: All processes can be processed with the combination of precision processing machines and skilled workers, and a system that demonstrates the highest efficiency is applied for each process with standardization.

Step 04. Review: Manufactured plastics molders are reconfirmed about potential defects in quality, design, and reliability, and this is systematized to apply immediately.

Step 05. Measuring: This stage is to determine whether all the development has been completed by measuring the quality of the final product with a 3D measuring machine or CMM etc.

Step 06. Product Released: It can be the truly finished product once the quantity requested from the customer is accurately and safely delivered.

Auto part mold is the general term for the molds used to manufacture all parts of automobiles. Including injection molds, stamping molds, forging molds, casting wax molds, glass molds, etc. When people talk about cars, the first thing they think of is the car body and all the spare parts. As a professional automobile mold factory and auto parts mould manufacturer, Green Vitality makes various types of car parts mould. We not only produces automobile bumper molds, automobile door molds, automobile instrument integration molds, but also automobile gear molds, automobile console molds, fender protection molds, side trim molds, and glove box molds, cup holder mold, console box mold, etc.

Consumer electronics refers to audio and video products for personal and home related broadcast and television, while consumer electronics molds including: TV molds, video recorder molds, camera molds, radio molds, tape recorder molds, stereo sound molds, phonograph molds, telephone molds, personal Computer molds, home office equipment molds, home electronic medical and health care equipment molds, automotive electronic product molds, digital camera molds, etc. Consumer electronic product molds are divided into ABS engineering plastic molds, polycarbonate molds, metal molds, etc. according to raw materials. Among them, ABS engineering plastics are the main materials for consumer electronic structural parts and are widely used in high-end consumer electronics manufacturers. product.

Mold is an important basic craft in manufacturing. Mainly used for mass production of industrial products. Industrial product molds cover key component molds in the fields of vending machines, POS machines, bank ATM machines, communication equipment, industrial water meters, electrical switches, industrial control boxes, and industrial control signal devices. With the rapid development of the plastics industry, the promotion and application of plastic products in aviation, aerospace, electronics, machinery, shipbuilding, automotive and other industrial sectors has become more and more extensive.

There are many injection molds for household appliances, such as fan molds, computer molds, air conditioner molds, washing machine molds, refrigerator molds, audio molds, water dispenser molds, dishwasher molds, etc. Of course, there are also some high-end products. All home appliances require injection molding. With the development of industry, the application of household appliances molds has become more and more extensive, the performance and quality requirements of household appliances molds have become higher and higher, and the production technology has been continuously improved.

We are one of the best daily necessities mold and plastic kitchen series mold manufacturers in China. The daily product molds we have made include: tableware molds, dish rack molds, plastic cutting board molds, plastic vegetable basket molds, drainage and basket molds, Spoon mold, plastic tray mold, basin mold, trash can mold, ice tray mold, bottle opener mold, etc.

Medical Device Component Plastic Injection Mold is another important part of our business. The services of the medical device component mold building include: culture plate mold, centrifuge tube/tube rack mold, tip/tube box mold, test tube mold, test tube rack mold, test tube plug mold, cuvette mold, sample cup mold, etc. We for the past ten years have also been privileged to provide plastic molds for Medical Device Component to customers all over the world, which have been of the highest quality and delivered with exceptional service.

Thermoset molding is an irreversible molding process by which malleable plastics are forced into a heated mold and formed into their final shape.

Aluminum die casting is often used in the automotive industry as a durable, lightweight alternative to steel and iron. Its low weight makes it an excellent choice for portable applications.

As one of the leading custom plastic mold manufacturers, Green Vitality Industry provides custom plastic injection mold & tooling solutions. We build all customer plastic injection molds in-house right here in Shenzhen China. Green Vitality Industry provides one stop injection molding service to our customers. It helps to save time and reduce product costs. We strive to be known in the markets serve as the best custom plastic molding company that operates to the highest ethical standards. Welcome to come and discuss with us, let us provide you the best service.

Green Vitality Industry offers custom plastic injection mold and tools for all kinds of industries. Green Vitality Industry provides cost-effective solutions and technical support from the first idea to the final product. Assist your product structure, save yourself the time-consuming, and become your cost-saving and reliable plastic mould supplier right here. Join us to be one of many satisfied clients!

Plate Machining

Mold Handling Weight

Average molds per month

Annual Mold Production

Normal Mold Delivery Time