Green Vitality Industry is a company specializing in one-stop service from mold design, product die-casting, and product post-processing. We specialize in the design & manufacture of various lighting, automobiles, furniture, electrical appliances, motor brackets, motor accessories with aluminum alloy, zinc-aluminum alloy die-casting parts, and plastic parts.

Aluminum die-casting is a kind of pressure-casting part. It is a die-casting mechanical die-casting machine equipped with a casting mold. The aluminum or aluminum alloy heated to a liquid state is poured into the feeding port of the die-casting machine. Aluminum parts or aluminum alloy parts with limited shape and size, such parts are usually called aluminum die castings.

| Material Capabilities | Aluminum alloy (AL A380) |

| Molding Processes | Die casting |

| Machine Size/ Clamping Force | 300 Tons |

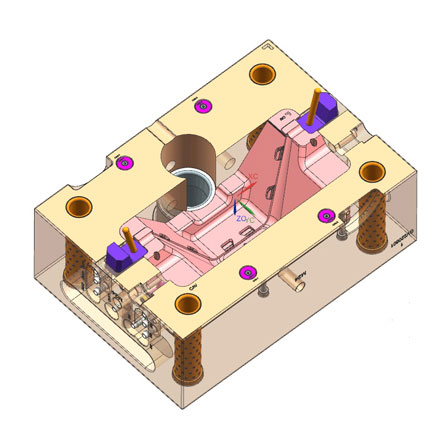

| Mold Size | 570X400X486 mm |

| Production Volume | 5,0000 units up to 100,000+ |

| Manufacture time (day) | 30-45 days |

| Mould weight | 765KGS |

| Part weight | 131.6g |

| Injection Cycle | 28 S |

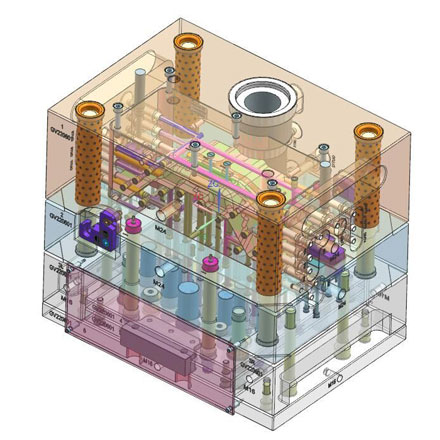

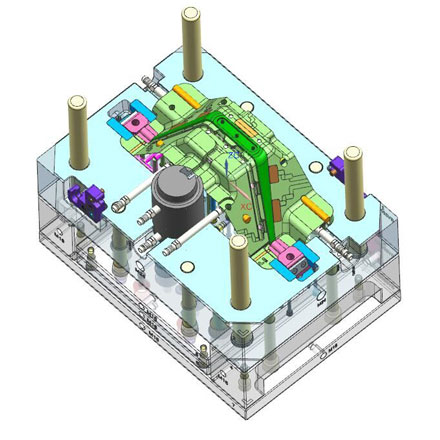

1. Mold design and development

We specialized in die casting mold development

2. Die casting production

Most machines can produce high precision die casting for enhanced, all kinds of die casting molding can be a large number of orders.

3. CNC machining center

Aluminum alloy dies casting, zinc alloy dies casting machining, die casting, and local processing.

4. Sandblasting/ tapping/ polishing

After sandblasting, tapping, and polishing processing products for all inspection.

5. Surface treatment

Electroplating, PVD, high-temperature paint, electrostatic spraying, chromium processing, electrophoresis.

6. Packaged goods

Qualified products packed in wooden case, effective protection products from being damaged during transit.

The surface treatment of aluminum alloy dies castings generally includes: powder spraying, baking paint, painting, oxidation, sandblasting, electroplating, etc.

1. Powder spraying: Powder spraying is to spray powder coating on the surface of the workpiece with powder spraying equipment. Under the action of static electricity, the powder will be uniformly adsorbed on the surface of the workpiece to form a powder coating. The powder coating is cured by high-temperature baking and leveling and becomes the final coating of different kinds of powder coatings.

2. Baking paint treatment: The real baking paint process is to spray with aluminum alloy after phosphating, and then bake after spraying. This kind of coating is not only anti-corrosion but also bright and wear-resistant, and it is not easy to fall off.

3. Spray paint: Spray paint is the name of the surface coating processing of industrial products. Spray paint processing suppliers also specialize in plastic oil injection, silk screen printing, and pad printing.

4. Oxidation treatment: The surface of aluminum alloy is oxidized, which is suitable for conductive oxidation, and aluminum or aluminum profiles are suitable for anodizing.

5. Sandblasting treatment: spray a layer of fine sand on the surface of aluminum alloy products to enhance the friction coefficient of the contact surface and enhance the reliability of the connection.

6. Electroplating treatment: Electroplating is the process of depositing metal or alloy on the surface of the workpiece by electrolysis to form a uniform, dense and well-bonded metal layer, which is called electroplating.