Plastic meal boxes mainly used for packing foods, so it need to be heat resistant and non-toxic,and could meet the requirements of environmental protectionso, we have to choose proper plastic materials, such as food grade PP,PS,starch material,Plant fiber material etc., then food container mould should be signed with high polish, good injecting and cooling systems to make sure the boxes could be with good shap and finish.For enhancing the speed, normally we suggest to produce plastic container mould on high speed injection machines.

As the wall thickness of the boxes is normally very thin, it's very important to design and make high-quality plastic food container moulds. An efficient mold cooling system can shorten the injection cycle and save more processing costs and time. We pay great attention to the mold cooling system and mold production stability. Our goal is to ensure customers run as little food container mold repair work as possible and be able to perform mass production efficiently and stably.

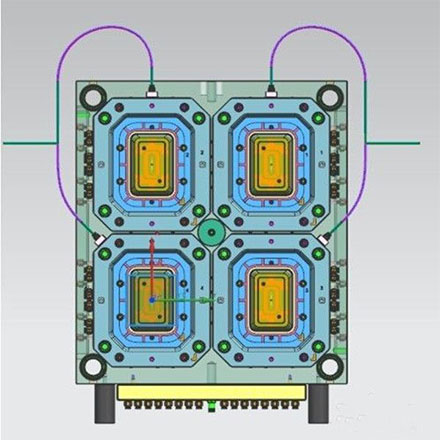

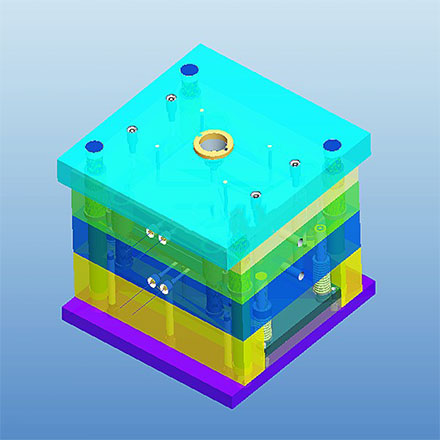

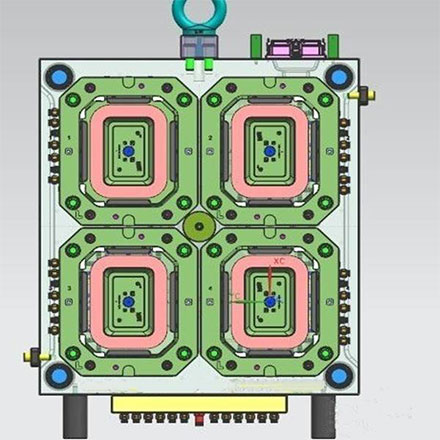

| Description | Plastic container mould |

| Plastic material | PP |

| Mould dimension(mm) | 1000*860*320 |

| Mould weight (T) | 2.2T |

| Mould cavity&core steel | P20 |

| Nos of Cavity | 1*4 |

| Manufacture time (day) | 45 days |

| Mould life | ≥500000 |

| Molding cycle (S) | 30S |

| Cooling line connector type | DME NS350 SERIES quick coupling, |

| Mold Characteristics | excellent cooling system design |

| Short cycle time |

Green Vitality, as a food container mould manufacturer, offers several distinct advantages in the production of plastic food container mould.

Precision Engineering for Quality Assurance: Our injection molded food containers are engineered with precision and durability in mind, ensuring that the resulting containers meet the highest quality standards. This precision guarantees longer lifespan, reduced replacement costs, and a superior standard of food storage and transportation.

Customization and Versatility: Green Vitality's plastic container mould is adaptable to meet diverse industry needs, from packaging to serving. We offer customization options, allowing clients to modify our molds to fit their specific requirements.

Longevity and Cost Efficiency: Our food container mold is constructed for long-lasting performance, reducing the need for frequent replacements. This not only saves on costs but also minimizes disruptions to production processes. We also provide ongoing support and maintenance services to extend the lifespan of our molds even further.

Support and Innovation: As a mold manufacturer, Green Vitality is dedicated to delivering top-notch plastic food container mold that is not only environmentally responsible but also versatile, durable, and tailored to the unique needs of our clients. Our commitment to quality and innovation sets us apart as a leading provider in the food container mold industry.

Designing about 2-3 different sizes of plastic meal boxes with the same lid could save the mold and production cost.

The thickness of the boxes is thin, so we need to design the food container mould with a good cooling system.

The materials of the boxes should be safe for hot food and meet environmental concerns.

To enhance production efficiency, you need to use a high-speed injection molding machine for plastic food container mould production.

Using robots to pick up the parts during production can also enhance production efficiency.

Following our construction to install and use the plastic container mould, to make sure there's no any damage for the mold and less repair.