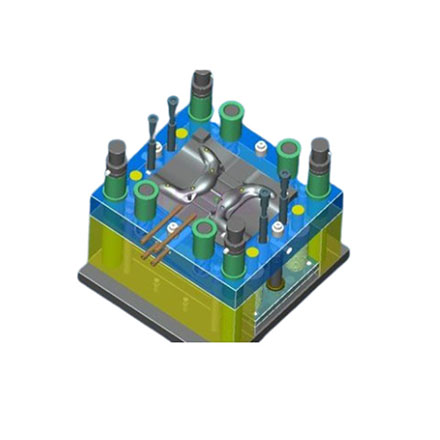

To increase the production efficiency, we need optimize the mold cooling system to shorten the cycle time. As a result, machining cost and time will be saved and the production efficiency increased. Green Vitality concerns a lot on mold cooling system and production stability. Our aim is to make customer run molds as less as possible for mold repair work, the best condition is free of repair work during mass production.

To produce a high qualifed Gamepad mold, we need to work hard on mold design and analyze injection, ejection and cooling system, so that the gamepad is without flash, sinkmark, deformation and easy demoulding. These are very important factors when making gamepad mold and injection the parts. Some gamepad mold is textured on the surface, while some are glossy. Green Vitality has rich experience in making both textured molds and polished molds. Except mold building, we also provide injection molding, painting, printing, electroplating, ultrasonic welding, assembly service.

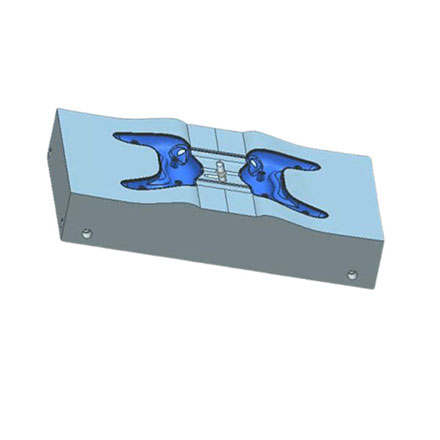

| Description | Gamepad Plastic Injection Mold |

| Plastic material | ABS |

| Part dimension(mm) | 180*140*70mm |

| Mould dimension(mm) | 400*550*460*mm |

| Mould weight (KG) | 730KG |

| Mould cavity&core steel | 718 |

| Nos of Cavity | 2 |

| Manufacture time (day) | 30 days |

| Mould life | ≥500000 |

| Molding cycle (S) | The 30s |

| Mold Characteristics | Multiple cavities mold |

| Slide and ejector pin structure |

Green Vitality offers a turnkey plastic molding solution from concept ideas to actual products. We make 3d printing, mold design, mold making, parts injection, surface treatment, and post-molding operation services.

State of art mold processing and parts testing equipment.

Professional engineers, technicians, workers, sales, and after-sales teams.

ISO9001:2015 quality control system and modern Japanese management

24hours a day, 7days a week, two shifts working to meet your output demands.

25years experience in plastic injection mold and molding field.

Our motto is Quality is First, Customer is Frist.