If the weight of each fan blade is not balanced, large vibration, high noise, and large wear of the rotating shaft will occur during high-speed rotation, which not only seriously affects product performance, but also The lifetime will also be greatly reduced. Therefore, fan products must ensure that the weight of each fan blade is balanced in order to pass the detection of the dynamic balance detector and adapt to the working environment of such products.

Fan blades are usually divided into shaft core circle, blade inner circle, and blade outer circle. If the concentricity of the shaft core circle, blade inner circle, and blade outer circle are not good, the fan blade will vibrate when it rotates, and the rotation will be unstable. Abnormal phenomena such as friction and noise occur around.

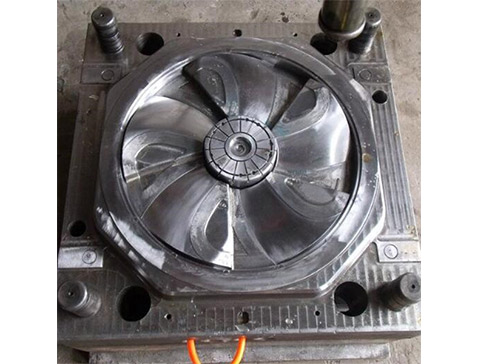

The plastic fan mold core in the existing fan blade mold is square, and the inner hole in the middle of the square mold core can only be processed by wire cutting. The concentricity cannot be guaranteed, and the concentricity of the inner circle of the blade, the outer circle of the blade, and the shaft core circle cannot be guaranteed, so the quality of the product is not high enough.

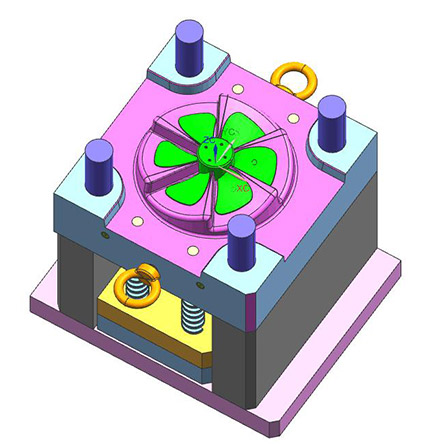

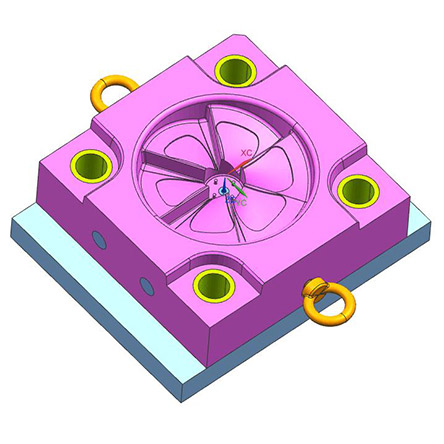

Also, the injection mold on fan blades must have high precision in centering the fan with the outside frame. GV Mold gives a special solution for the centering location, therefore, after the assembling, the plastic fan and the frame run without any noise of testing.

| Description | Fan Blade Plastic Injection Mold |

| Plastic material | ABS |

| Mould dimension(mm) | 320*380*370 |

| Mould weight (kg) | 200kg |

| Mould cavity&core steel | S136 |

| Nos of Cavity | 1*1 |

| Manufacture time (day) | 30 days |

| Mould life | ≥300 000 |

| Molding cycle (S) | 35s |

| Mold Characteristics | High concentricity requirements |

| Short cycle time |

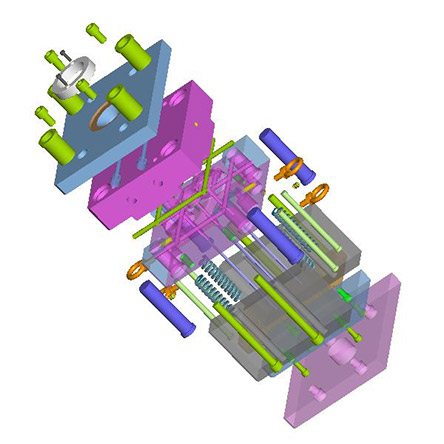

The shape of the plastic fan blades is relatively simple. The first requirement is the principle of coincidence of the center of gravity. The size and thickness of all blades should be the same to ensure that the center of gravity of the product is located in the center of the plastic fan part. The second requirement is dynamic balance, that is, balance while rotating. These two requirements put forward higher requirements for the mold on fan blades, that is, on the premise of ensuring the reasonable design of the fan blade mould, improving the mold manufacturing process, and improving the mold manufacturing quality.

In addition to paying attention to balance in the plastic fan mold design process, the balance problem in mold processing is also important. The manufacture of mold cavity & core needs to be directly processed by a high-speed machine, and high-quality processing cutting tools are required. We should make sure each blade has the exact same shape and dimensional tolerances. After all machined, it should be inspected by 3-coordinate, and after all of the dimensions meet the tolerance, then fit the mold on fan blades and assembly it.

Our factory conforms to the ISO9001:2015 standard.

One-stop service provider from the initial product design and development to the entire stage of mold making and fan mould production and delivery.

We adopt Japanese management to ensure each process is in control.

The whole set of documents for project management, from NDA to shipment files.

Long-term and well-cooperated steel supplier to ensure a good price and quick delivery.

Over 95% of designers & engineers are with more than 10 years of experience in the plastic mold industry.

All project engineers could discuss projects in English to save communication time.