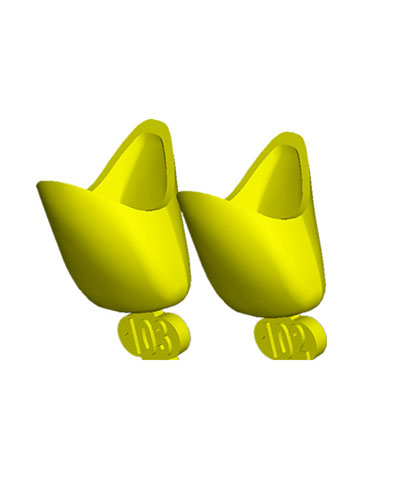

Dental medical instruments include a dental mobile phone, oral cell phone sterilizers, dental forceps, braces, diggers, and other surgical instruments, manual dental instruments, dental rotary instruments, dental-injection instruments, root canal instruments. Green Vitality can customize the mold of various dental products.

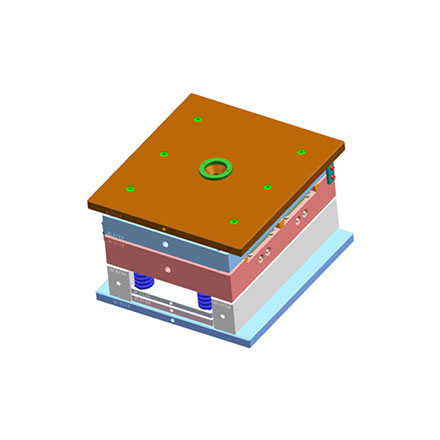

Our mold materials and accessories are made of high-quality products from genuine manufacturers. The mold processing and production are equipped with advanced mold processing and testing equipment at home and abroad. It has the advantages and characteristics of long mold life, short injection cycle, and low maintenance cost during mass production.

| Description | Bicuspids Crown Mold |

| Plastic material | PP |

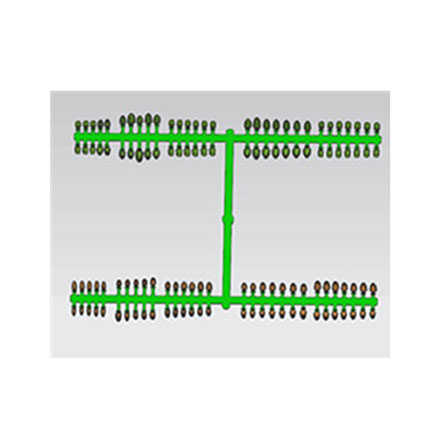

| Cavity No | 1*2 cav. |

| Mould size | 550*600*391 mm |

| Mold steel | S136 |

| Mold life | 500 K |

Every product is like a work of art, we pay attention to the fineness of every product and mold.

We focus on efficiency as you do, and promise quick response and quick production.

Communicate as easily as your internal team and use technology to solve problems efficiently.

Both the mold and the production plan consider the cost from the perspective of the customer.

Mold material

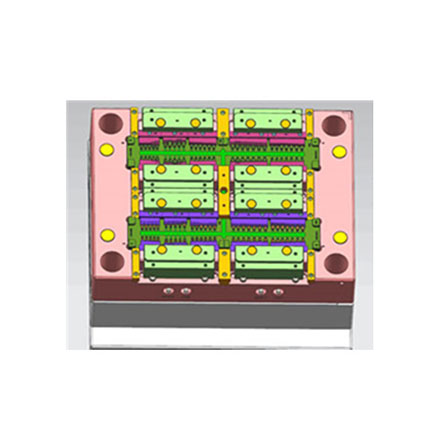

We use high-strength mold materials for medical mold bases, including 2083, P20H, 718H, etc.; For the main part of medical molds, including cores, cavities, return plates (sleeves), and related inserts, we use Advanced plastic mold steel, including 2083, 2344, 2311, 2316, 2738, S136, etc;

Design of the mold

Drawing on European and American medical mold design, combined with our rich experience, using innovative mold design, the quality of medical molds is perfect;

Mold parts processing

Use high-speed CNC machining centers to process molds for standardized operations; ensure the accuracy of each medical mold part;

Fast cycle times

Apply the perfect cooling water channel on the medical mold, combined with the use of fast cooling material, to optimize the cycle time, make the production more rapid and stable, and improve the production efficiency;

Mold delivery time

Fast delivery time, the delivery time of medical molds is generally controlled within 60 working days;