Green Vitality provides customized mold manufacturing services, according to your mold specifications (including mold parts standards, injection molding machines, plastic materials and shrinkage, molding cycle, mold life, etc.). In general, the mold manufacturing cycle is between 20 days and 60 days, depending on the size of the part, the complexity of the mold structure, the accuracy of the mold, etc. We extensively customize injection molds for customers in various fields, including automotive, consumer electronics, household appliances, industrial products, daily necessities, medical products, and other industries. Our professional sales team should keep posted on project progress to customers every week so that customers can keep abreast of the latest status of their projects.

Whether you need soft tooling or steel mold, Green Vitality provides you with expertise and craftsmanship to deliver quality molds and mold services.

In-House Full Service Capability

Existing Tooling Transfers

Off-Shore Mold Building Alliances

Mold Management/Mold Maintenance

Mold Repair

Mold and product Design

Engineering Support

Tool History Documentation

Molding problem Solutions

Moldflow Analysis

Tolerance limit Control (+/-)

Grade A2

0005 in. Within Cavity Shape

Grade A1

005 mm. Within Cavity Shape

Precision Machining

Plastic injection mold is constructed by two main methods: standard machining and electrical discharge machining(EDM).

In modern CNC systems, mold design and manufacturing processes are highly automated. The mechanical dimensions of the mold are determined by computer-aided design (CAD) software and then converted into manufacturing instructions by computer-aided manufacturing (CAM) software. The "post-processing" software then converts these instructions into specific commands required by each machine used to create the mold. Then load the obtained command into the numerically-controlled machine tool. With numerically-controlled machine tools, computers can control the movement and operation of milling machines, lathes, and other cutting machine tools.

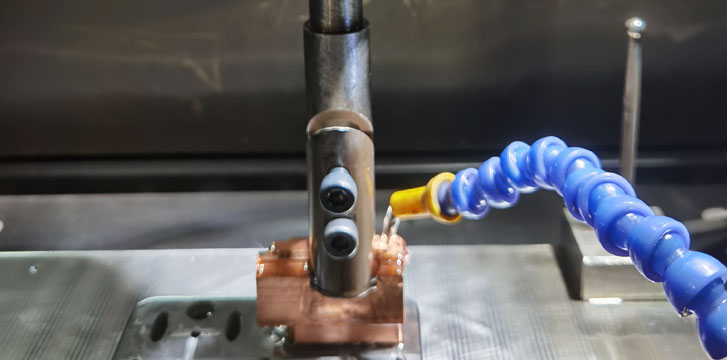

Electric discharge machining (EDM) has been widely used in mold manufacturing. EDM is a process in which the desired shape is obtained by using electrodes made of graphite or copper. It is then mounted on the EDM and placed on the workpiece submerged in the dielectric fluid. The EDM process can produce shapes that are not possible with conventional CNC machining. EDM process allows pre-hardened molds to be shaped and eliminates the need for additional heat-treating, fine EDM finish serves to be the final part finish without any polishing of the mold cavity.