The family mold is used to produce injection parts for liquid filtration and flow monitoring and control systems.

These accessories are customized made for Rotational Filter and Flow Limiting equipment and devices. There are two parts which are assembled together, one is hat shape, one is small ring shape. When connect the ring part onto the hat shape part, then install to the filtering and flow limiting apparatus.

| Description | CLoche-Bague PP parts |

| Plastic material | PP or PEHD |

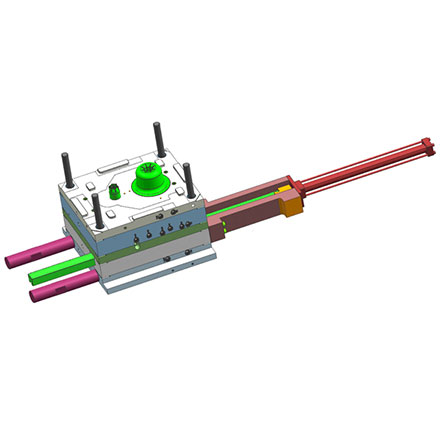

| Mould dimension(mm) | 685*550*1014 mm |

| Mould weight (T) | 1350 kgs |

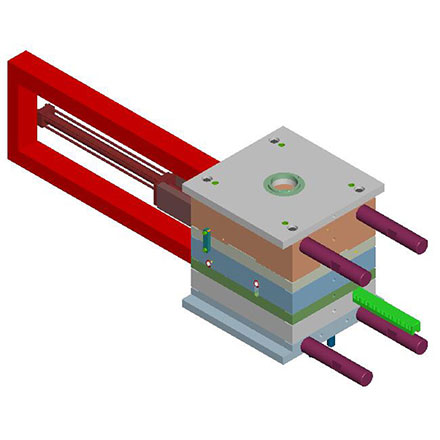

| Mould cavity & core steel | NAK80 |

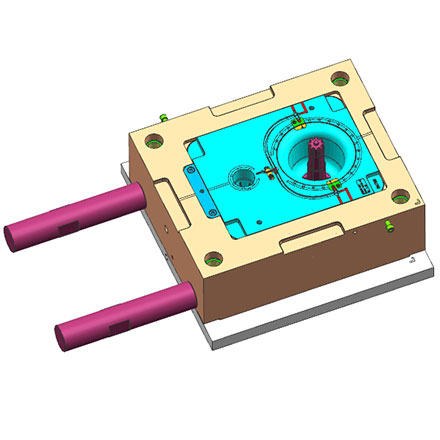

| Nos of Cavity | 1+1 |

| Manufacture time (day) | 40 days |

| Mould life | ≥30,0000 |

| Molding cycle (S) | 50 S |

| Cooling line connector type | quick coupling |

| Mold Characteristics | Hydraulic Cylinder to drive the gear and driving wheel for unscrewing mechanism. |

The screw thread section must be assembled perfectly.

There should be with draft angle (say 1 degree) for the inner position of the hat shape part.

It is better to design the radius positions without sharp edges.

In the design of the injection mold, the family mold is an effective way to increase productivity and save cost.

Family Mold is containing different shaped cavities, in one shot, each cavity produces a different structure component that is assembled into a full set apparatus with same color and texture as much as possible.

Because the structure of each cavity is different, it is imperative to design the mold with balanced processing performance.

The gating system of multi cavity family mold has two ways: natural balance and unnatural balance. Natural balance system is of exactly same cooling conditions and runner, gate, cavity at the same dimension. In the non-natural equilibrium gating system, because the length of the runner to each cavity is different, it is necessary to adjust the size of the runner so that the plastic melt can feed each cavity at the same time with the suitable forming pressure and temperature.