Toilet seat casting mold quality points: cover mold cycle, cover mold life, Parting line whether there are sharp edges? Is the cover wall thickness even? How to make the covers of toilet seat casting mold are light and strong? How to design a good exhaust ? How to make your toilet cover polish durable? How to judge the molding cycle? how to set up the toilet temperature?

Explore our selection of toilet seat casting molds for sale. Green Vitality's plastic toilet seat molds are designed for efficient and reliable production. Crafted with precision, these molds facilitate the manufacturing process. Find the right solution for your production needs with our durable and high-quality toilet seat casting mold.

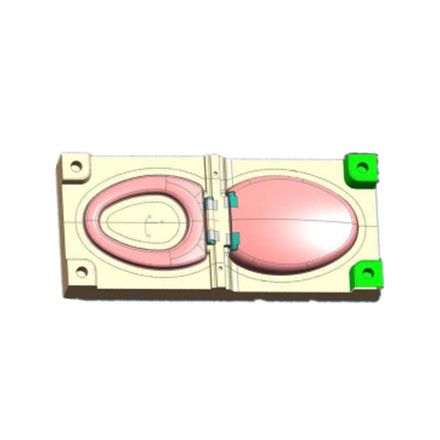

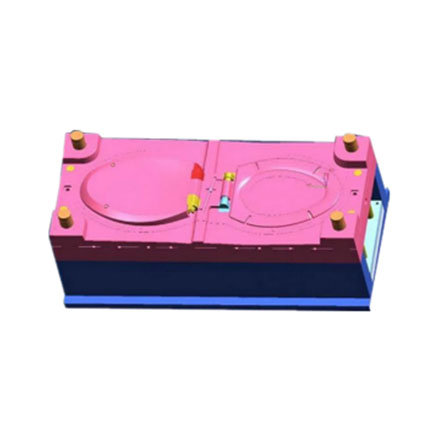

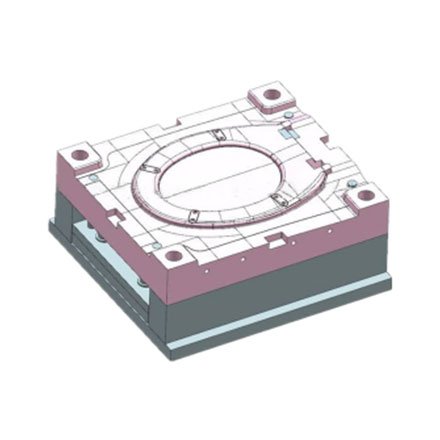

As the toilet cover need to be strong and durable, the surface need smooth and high polished, many defects may be in injection molding production, including rhymes, poor fusion, black spots, black lines, color difference, burning a so on, we choose PP for the part material,to ensure the toilet seat cover mould quality and toilet seat cover mold life, choose steel with right hardness and design the plastic toilet seat mold with reasonable/reliable construction and movements. The mold cycle is settled to meet the requirements of lowest cost. Ribs are added to strong the covers. We make side core pulling bodies for demolding and use hot runner to enhance the production quality and efficiency,and good cooling system of the toilet seat cover mould is also very important.

| Description | Plastic toilet seat cover mold |

| Plastic material | PP |

| Mould dimension(mm) | 730*710*560 |

| Mould weight (T) | 2.2T |

| Mould cavity&core steel | H13 |

| No. of Cavity | 1*1 |

| Manufacture time (day) | 55 days |

| Mould life | ≥500000 |

| Molding cycle (S) | 50S |

| Mold Characteristics | excellent cooling system design |

| Short cycle time |

Precision Engineering: Our toilet seat cover mold is crafted with precision, ensuring each toilet seat cover mold is consistent and accurate.

Eco-Friendly Materials: Green Vitality is committed to sustainability, using environmentally responsible materials in our toilet seat casting mold production.

Industry Leading Quality: Our toilet seat mould for sale are known for their exceptional quality and innovation, setting industry standards for toilet seat casting mold manufacturing.

Innovation: We continuously strive to improve and innovate, ensuring our mold on toilet seat cover stay at the forefront of the industry.

Green Vitality also offers tailored solutions for your toilet seat cover production needs. We understand the importance of adaptability in manufacturing. Our plastic toilet seat mold can be customized in various aspects, including size, shape, design, and material compatibility, ensuring they perfectly align with your specifications. From ergonomic and sleek designs to versatile materials, we create molds that meet your unique requirements. Whether you need standard or specialty toilet seat cover mold, our expertise guarantees a high-quality, cost-effective solution for your production processes. Trust us to deliver mould on toilet seat that align with your vision and performance standards, ensuring consistency and reliability in your manufacturing.

Choosing the right material for the cover, PP could make the parts with good strength, good rigidity, good dimensional stability, and good coloring performance.

Designing the proper injecting system to ensure the plastic material could be heating melt well and venting.

Choosing the good mold material and inserts to ensure the high quality of the toilet seat casting mold.

Using the hot runner for cost-saving and enhancing the quality of the parts.

Using robots to pick up the parts during production can also enhance production efficiency of the toilet seat mould.

Following our construction to install and use the toilet seat cover mould, to make sure there's no any damage for the mold and less repair.