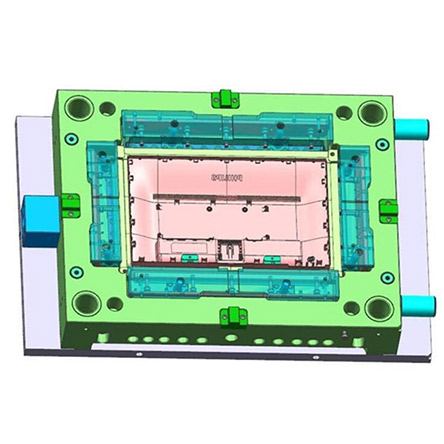

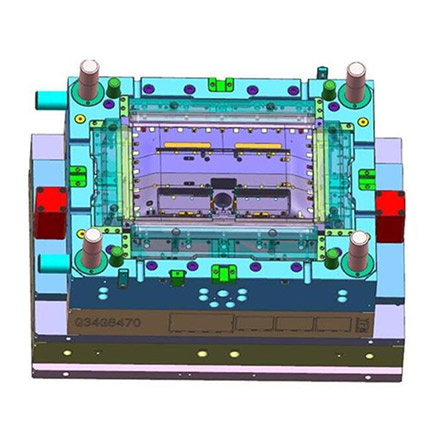

TV screen frame mold is used to produce TV screen frames, it should be strong and assembly well with the screen. It has an undercut to lock the screen inside stablely. For the LCD TV mould, we usually make one cavity mold, because of its big size, the injection machine needs 350T to 1000T upon the frame size. Green Vitality has been made screen mold more than 1meter.

To produce a high-quality TV screen frame mold, we need to work hard on mold design and analyze the injection, ejection, and cooling systems, so that the screen frame is without flash, sink marks, deformation, and easy demolding. These are very important factors when making LCD TV mould and injection the parts. Our aim is once the injection parameter is set by our customers, the mass production will be continuously good, and no need to repair.

| Description | TV LCD screen frame mold |

| Plastic material | ABS |

| Part dimension(mm) | 560*343*52mm |

| Mould dimension(mm) | 1150*750*786mm |

| Mould weight (KG) | 4000KG |

| Mould cavity&core steel | H13 |

| Nos of Cavity | 1 |

| Manufacture time (day) | 50 days |

| Mould life | ≥500000 |

| Molding cycle (S) | The 50s |

| Cooling line connector type | DME NS350 SERIES quick coupling |

| Mold Characteristics | big mold more than one meter |

| excellent mold design, without any defects | |

| Short cycle time |

Choose a higher definition for a better view, protect your eyes.

Choose a famous brand to get high-quality TV and good after-sales service.

If you need to install the TV screen on the wall, please make sure you have fixed it firmly.

You need to check the socket, plug, and the wires frequently, once you find any broken on them, you must replace the broken parts, this is very important for your family's safety.

If you leave home for a holiday or don't watch TV for a long time, please remember to open it from time to time, this can increase the service life of your TV.

You must take care of your children and teach them do not play around with the TV.