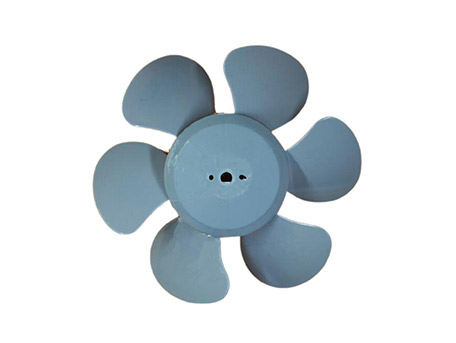

GV Mold has rich experience in home appliance molds (such as television, refrigerators, fans, washing machines, air conditioners, and various smart home appliances). We can provide turnkey solutions for high-precision houseware moulds according to customers' ideas, from raw material selection advice, product design optimization, mold flow analysis, mold manufacturing, mold design improvement to plastic parts production, assembly, packaging, delivery.

Before making home appliance mould, we usually verify the plastic product & mold in the following steps. In this way, we can speed up product development, effectively control mold costs, reduce mold repair costs in the manufacture stage, and fully verify product performance as much as possible to save time and cost.

Provide quote in 24hours with drawings and requirements if urgent.

Over 95% designers & engineers are with more than 10 years experience in plastic mold industry. and all project engineers could discuss projects in English to save communication time.

Strictly conforms to ISO9001:2015 quality control system.

Technical support from the initial product design to the entire stage of mold making and product production and delivery.

That's great, do a drawing with measurements and as much information as you can, or send your parts to us. we can support from an idea to the finished item.

The volume requirements of the product are the main consideration when deciding to use injection molding as a manufacturing process. If you need more than 1000+ products, plastic injection moulding is probably the best solution. Because the mold is expensive, it will save you more cost when you need mass production.

The price depends on:

• Size of the mold

• Lifetime of mold

• The number of cavities

• The material the mold is made of ie. Steel or aluminum

• The surface of the finish required

• The complexity of the part

The best way is to send an email to me or call us.

We will go through all your requirements and start the right foot with you.