Provide complete solutions from product design/mold manufacturing/injection mass production.

Provide professional medical consumables and medical device molding development and injection molding production services for companies engaged in biotechnology technology development and technical services.

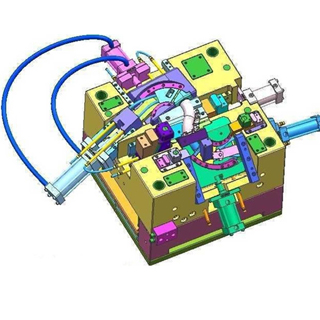

After the medical injection parts have been fully verified and approved, the official steel mold is developed. The official steel mold can produce 50000, 100000, or 300000 parts according to the different steel materials used, and select the appropriate steel material according to the planned output.

Assembly using pneumatic or manual methods to join molded parts

Ultrasonic bonding to create a durable bond between two or more components

Pad printing to add logos, instructions and other designs on the surface of your molded parts

Customized packaging to meet your product packaging requirements

The medical-grade plastic materials we use for medical injection molding have high molecular weight and feature chemical and heat resistant properties.

Our smallest machine is 90 tons and our largest is 400 tons.

738, 738H. NAK80, S136. etc. the mold steel is dependent on the mold life and product quantity. We can select the steel type according to your request.